TurboCycler 2 Thermal Cycler with 96-well Sample Block (110V)

TurboCycler 2 thermal cycler is designed specifically to enhance PCR efficiency and accuracy. It is equipped with a 7” sensitive touchscreen and a friendly graphic user interface, which makes operation highly intuitive. With flexible ramp rate and gradient temperature control, TurboCycler 2 greatly increases PCR accurate optimization. The Wi-Fi function enables you to monitor the PCR run status anytime remotely with walk-away convenience.

| Catalog number | Unit Size | Description |

|---|---|---|

| TCST-9612 | Each | TCST-9612: Gradient TurboCycler 2 with 96-well Sample Block (110V) |

PRODUCT OVERVIEW

TurboCycler 2 thermal cycler is designed specifically to enhance PCR efficiency and accuracy. It is equipped with a 7” sensitive touchscreen and a friendly graphic user interface, which makes operation highly intuitive. With flexible ramp rate and gradient temperature control, TurboCycler 2 greatly increases PCR accurate optimization. The Wi-Fi function enables you to monitor the PCR run status anytime remotely with walk-away convenience.

Enhancing PCR Efficiency and Accuracy

Flexible Ramp Rate Control: from 0.1 – 5.5 ℃/sec to meet the need for the CRISPR related assays .

Fully Adjustable Lid Temperature: can be set between 35 and 120 °C for virtually any type of experiment including NGS pre-treatment.

Gradient Optimization: range from 1 to 30 °C enables optimal experimental conditions in a single PCR run.

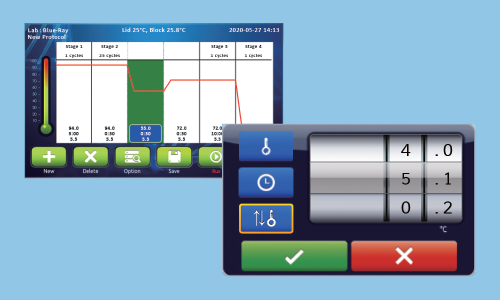

Easy to Control: The sensitive 7” capacitive touchscreen enables easy operation even with laboratory gloves.

Friendly User Interface: The graphic interface is easy to use, making the adjustment of experiment parameters such as temperature, time and cycle quick and simple.

Efficient Remote Monitoring: Monitor your PCR status remotely anytime on your mobile device via the free TurboApp.

Video

SPECIFICATIONS

Specifications

Sample Block

- 96 Well, Gradient Block

- Compatible with regular profile or low profile 0.2 ml PCR tube, strip, non-skirted, semi-skirted and full-skirted 96-well plate

Block Temperature

- Block Temperature Range

- 4.0 - 100 °C

- Max. Heating Rate

- 5.5 °C/sec

- Max. Cooling Rate

- 3.3 °C/sec

- Temperature Accuracy

- +/- 0.3 °C

- Temperature Uniformity Across Block

- +/- 0.3 °C

- Adjustable Ramp Rate

- 0.1 - 5.5 °C/sec

Gradient Temperature

- Gradient Direction

- Horizontal across the block

- Gradient Temperature Range

- 30 - 100 °C

- Gradient Temperature Difference

- Max. span 30 °C

Heater Lid

- Temperature Setting Range

- 35 - 120 °C or off

- Temperature Accuracy

- +/- 1.0 °C

Software

- Portability of Protocols

- Save and transfer to computer or TurboCycler 2 via USB flash drive

- Stored Program No.

- > 4000 sets

- Registered User Folder No.

- 100 sets

- User Folder Password Protection

- Yes

- Run Status Report

- Yes, HTML output and transfer via USB flash drive

- Real-time Temp. Profile Export

- Yes, CSV output and transfer via USB flash drive

- Tools

- Tm calculator, Copy number convertor, Master mix preparation wizard

General

- Display

- 7” color LCD with capacitive touch panel

- Data Port

- 1 USB Type-A front port for USB flash drive

- Heated Lid

- 35 - 120 °C or off

- Auto Restart after Power Outage

- Yes

- Remote Monitoring via Wi-Fi

- Optional

- Footprint Dimensions (H x W x D)

- 225 mm x 245 mm x 415 mm

- Weight

- 9.5 kg

- Power Supply

- AC 100-240 V, 50/60 Hz, 750 W

- Certification

- CE, RoHS

Faqs

1. Compressor Mat and Low-profile PCR vessel

The low-profile PCR vessels is design to reduce the overhead space above the reaction solution inside the vessel.

During the thermal cycling, the water in the solution evaporate and fill up the overhead space, causing the concentration increase of the reacting solution.

The smaller overhead space, the fewer water evaporated, thus reduce the concentration change of the solution when heated. This will be helpful especially when you are doing low volume reaction.

In general, the low-profile PCR vessels are 5 mm shorter in height than the regular PCR vessels.

In order to maintain the pressure from the cycler lid to the vessels, please applied the compressor mat for the experiment and set the lid to heat to 120°C.

2. What is the function of lid? What is their effect on the evaporation? Does our lid temperature cycle with experiments? Do the competitive units do? At 4 °C step what temperature is lid?

There are three different setting of temperature for the lid:

– The propose of lid heating is to avoid severe condensation in PCR tube during reaction.

– Evaporation is related to the pool sealing of the PCR vessels. However, the proper pressure from the lid to the sealed vessels will help to maintain the integrity of the seal, thus help to prevent evaporation.

– The Lid heating doesn’t do the cycling. No, the competitive units doesn’t do the cycling as well.

– While the block start to goes down under 30°C, the lid heating is stopped. The temperature of lid will gradually decrease. The competitive unit does it as well.

3. Condensation V.S. Evaporation

– Condensation inside the tube is mainly caused from the tube stayed at lower temperature (e.g., 4°C) after the run for a long period of time. It occurs to all the cycler. This phenomenon is similar with putting a bottle of water in refrigerator and you will see the condensation in the bottle.

– Evaporation means that the evpor of the contents in the tube is released to the envirament. It is definitely associate with the integrity of the vessel sealing.

– If the seal or the vessel cannot withstand the temperature cycling during the run, they may have serious deforming. It is so severe that the deforming tear off the seal. This is caused from the quality issue of plate and seal, because these consumables need to stay intact at cycler.

4. When I start a run, the block hold for several minutes then start to heat. Why?

The lid of the cycler need to be heated to proper temperature first then the block start to heat.

According to the setting of the lid temperature, the room temperature and the usage of the compression mat, it can take 2-8 minutes for the lid the finish the heating.

5. When the power comes back after a power failure, does the TurboCycler start running again?

For the power-failure-during-a-run situation, when the power come back to the unit, the unit will start from what it was running (without touch the power switch) and finish the protocol. Also, if the power failure for long time, the unit will still start (after the power back on) as well but it will take few seconds or minute for lid module heat up.

After the lid module reach to the setting temperature, the protocol will be continued. This design will protect the PCR experiment.

This function named “Auto-restart after power outage”

6. Can TurboCycler run overnight?

Yes! But we would not recommend you do that really often.

Running your cycler overnight at 4°C potentially reduce the life cycle of the instrument. In most application, 16°C instead of 4°C for overnight storage can well-protect your DNA sample.

7. Whether the ramping rate of TurboCycler is adjustable?

Yes! There are two options of the ramping rate for the TurboCycler, Hi and Low.

Hi for the full ramping power that will speed up your experiment and Lo for the 50% of the ramping power that can mimic the running condition on the other older generation cyclers.

8. What’s the temperature range of TurboCycler lid?

There are three different setting of temperature for the lid: 120°C (for use with low-profile vessel + compression mat), with extra 3 min pre-heat

105°C, Heater off

9. Is the block of the TurboCycler interchangeable?

There is only one block configuration for the TurboCycler so far, so it is not interchangeable.

However, if there is any service need to be done with the block, it can be easily disassembled and sent back to us for service.

We're here to help

We're here to help